X-Ray Diffraction Analysis

Objects of study

Single- and multi-component polycrystalline and nanocristalline systems.

Applications

X-ray powder diffraction is used for the study of the composition, structure, microstructure, and phase conversion dynamics in the single- and multi-component polycrystalline and nanocristalline systems.

Following estimations are performed:

- Qualitative phase analysis of multi-component systems with the particle sizes (coherent scattering domains – CSD) D >5 nm. Phase determination is carried out with diffraction data base PC-PDF. As a rule, it is required to know the component composition of the sample. The phases with the content more than 1% mass are detected for roughly dispersed materials (D >50 nm).

- Quantitative phase analysis of the materials with 2–5 phases (D >50 nm) is accomplished by the methods of internal and external standards and construction of calibrated curves with application of mechanical component mixtures and full profile analysis (an accuracy of determination is ± (2–5)% depending on the quantity and dispersity of phases).

- Determination of microstructure parameters (particle sizes, microstrains, stacking faults). For conventional measurements the approximation method based on the determination of half width of diffraction peaks is used. With this method it is possible to estimate the average CSD in the range 5–150 nm, value of microstrains, for metals – concentration of stacking faults. More detail study of microstructure may be made on the basis of full profile analysis of the whole diffraction pattern or by harmonic analysis of the separate band profile.

- Determination and refinement of crystalline structure parameters. The unit cell parameters may be specified on the basis of powder diffractograms for crystals of any syngony by the least square method. There are available the programs of interatomic distance calculation and theoretical X-ray patterns for the given crystalline structures. The crystalline structure models (atoms coordinates, occupation density, isomorphous substitution, heat parameters) are specified by the integral dependencies of diffraction peaks and/or by the Rietveld method.

- Study of the short-range order in the amorphous and ultra-dispersed (D<5 nm) materials by the radial electron density distribution – REDD. The average interatomic distances, coordination numbers, root mean square atomic displacements are defined. On the basis of these structural data the phase composition, structure, dispersity, crystallinity and degree of interaction of specific components in multi-component system may be estimated.

- High temperature and in situ X-ray diffractometry. Phase composition, parameters of crystalline structure and microstructure are studied at the raised temperatures: up to 1400°C in the air, vacuum and inert mediums, up to 900°C in active gaseous phases, including hydrogen, CO, hydrocarbons, gas mixtures with steam.

Information to be obtained:

dynamics of phase composition variation, dispersity, structural parameters of specific phases (unit cell parameters, structural type, characteristics of an atomic structure deviation from the ideal one under the temperature and medium influence and others), kinetic parameters of phase transitions.

The method becomes a necessity under the reversible action of the specific conditions onto the substance and might be used in the various fields of science and engineering (catalysts, minerals, metals and any chemical compounds).

Additional possibilities

1. In the Siberian Center of Synchrotron Radiation of the Siberian Branch of the Russian Academy of Sciences (SB RAS) jointly with the Institute of Chemistry of Solid and Mechanochemistry of SB RAS a precise diffractometer allowing to obtain the diffraction patterns with a resolution (peak half width) up to 0.03° by 2Θ in the wide range of wave length 0.05 – 0.4 nm. Due to the possibility of wave length variation the anomalous scattering method might be used for the study of isomorphous substitutions and for the construction of the partial functions of radial atom distribution.

2. An original software for the simulation of real structure and diffraction patterns of ultra-dispersed and partially disordered systems has been developed. With this technique on the basis of a full profile analysis of the diffraction pattern it is possible to obtain the detail information about CSD, micro-strains (I and II type), type and concentration of defects of layers deposition and others. It is possible to study the real structure of a lot of objects, including crystals with a developed micro-domain structure and crystals with very small physical sizes, paracrystals, turbostrate structures, various polytypic and modulated structures as well as diversity of real systems in which various sources of disordering of the long-range order simultaneously take place.

XRD and HRTEM

Experimental (asterics) and theoretical (solid line) X-ray diffraction patterns

of aluminum-magnesium spinel (R1 = 4.5 %, Rp = 7.6 %)

A full profile analysis of X-ray diffraction images allows not only to refine the average crystalline structure (atoms coordinates in the elementary cell, positions occupation, heating parameters) but to define the structure of extended defects as well. The example given for the non-stoichiometric aluminum-magnesium spinel displays these possibilities. The theoretical diffraction image corresponds to the experimental X-ray pattern with a high accuracy.

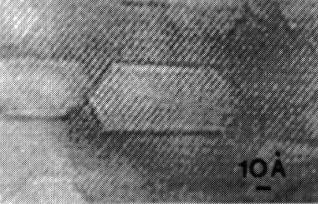

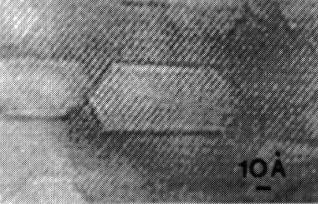

The local structure and concentration of the planar defects are determined from the X-ray diffraction data. They constitute the dislocation walls forming the pseudo hexagonal closed loops that are visualized by the technique of high resolution electron microscopy (HRTEM).

Projection of spinel structure on [001] plane:

Experimental high resolution micrograph of the defect in the structure of aluminum-magnesium spinel

/Journ. Struct. Chem. [JSTCAM], v.32, p.325 [1997]/

Instrument facilities

Siemens D500, URD-6, URD-63, HZG-4B, HZG-4C, Bruker D8 diffractometers (Germany); high resolution diffractometer with synchotron emission in the Siberian Center of Synchotron Radiation of SB RAS. The X-ray tubes with the copper and molybdenum anodes are applied on the series-produced diffractometers. Bases of X-ray diffraction powdery (PC-PDF) and crystallostructural data are available.

Samples requirements

Samples in the form of powder (0.5–2 cm3), plates, tablets (not less than 5x5 mm2) with the indication of chemical composition.

Leading scientists and their research interests

Prof. S.V. Tsybulya. Full profile analysis and study of the defective structures.

Prof. L.M. Plyasova. Regularities of the formation of complex oxide catalytic systems, X-ray in situ.

Prof. E.M. Moroz. Study (including by REDD method) of the structure of oxides, carbon-containing materials, highly dispersed bulk and supported metals.

Small-Angle X-ray Scattering (SAXS)

Objects of study

Solid and fluid samples in the form of surface slicks, plates, coatings, powders, tablets, pellets, solutions, sols and gels.

Applications

- Finding information of internal structure of substances to obtain direct data about the shapes and scattering nanoparticles distribution (heterogeneities of electronic density) from 1 to 200 nm in size.

- Determination of values of some nanoparticle’s structural invariants in monodispersed systems: radii of gyration (volumetric, cross section and thickness); a volume and area of surface; the maximum size in a particle and correlation length.

- Investigation of nanoparticles size distribution in polydispesed systems.

- Determination of specific surface and fractal of internal structure of samples.

- Study of macromolecular mechanisms of equilibrium interactions between nanoparticles and complexes in binary mixtures of solutions, sols or gels in chemical and biochemical processes to determine reaction stages, stoichiometry of the complexes formed and thermodynamic characteristics (equilibrium constants).

Instrument facilities

Small-angle X-ray diffractometer of Siemens (Germany), Anton Paar and Hecus-Braun firms (Austria) with small-angle camera Kratky (“Compact camera”). The camera allows to measure X-ray scattering on solid and liquid samples in the area from the smallest angles up to 7 grad; the maximum resolution of the camera is 300 nm; the X-ray tube with a copper anode (λCuKα = 0.154 nm) is applied; there is ability of samples termostabilization from 0 up to 70°C within ± 0,1°C.

Samples requirements

Thin films, tablet, plate, coating by the size not less than 1x10 mm2; powders, pellets, solutions, gels and sols with a volume of a disperse phase not less than 0.05 cm3.

Leading scientists and their research interests

Prof. F.V. Tuzikov. Study of molecular mechanisms of chemical and biological catalysis, nanostructural analysis of substances, analysis of the components of blood for medicine, small-angle radiography in situ, development of scientific equipments.

Differential Dissolution Phase Analysis (DDPA)

Objects of study

- Solid inorganic substances both crystalline and amorphous.

- Crystals, powders, ceramics, thin films and others may be studied by this method.

Applications

- The qualitative and quantitative phase analysis.

- Microphase analysis is possible:

- phase determination in the sample with the weight up to 1 mg;

- determination of the extrinsic phases;

- definition of the phase extrinsic component distribution.

The method may be used in regulation of phase composition during preparation and exploitation of the heterogeneous catalysts, high temperature superconductors, luminescent solids, magnetic materials, inorganic pigments, products of mechanochemical activation, for the study of archeological findings and others.

Simultaneous phase classification of 38 chemical components is possible.

The sensibility of component determination is up to 10–3 mkg/ml.

An error of the stoichiometric coefficient estimation in the phase formula is up to 10%.

Method uniqueness: determination of the empirical phase formula and their quantitative content in multi-phase samples is performed without reference samples of the corresponding individual phases.

Instrument facilities

The method is based on the regularities of stoichiography and dynamic diffusion regime. Inductively coupled plasma atomic-emission spectrometer (PST “Baird”) is used as a detector.

Samples requirements

Sample weight – from milligrams up to grams.

Leading scientists and their research interests

Prof. V.V. Malakhov and Dr. A.A. Vlasov. Phase analysis of the solid inorganic substances.

Extended X-Ray Absorption Fine Structure (EXAFS) Spectroscopy

Objects of study

X-ray amorphous liquid and solid samples, i.e. the samples for which X-ray diffraction structural methods are unsuitable.

Applications

The structure of the local atom surroundings of the selected chemical component (coordination number, interatomic distance, Debye factor, type of the neighboring atom) is studied. Depending on the technique applied the following parameters are analysed: volume, surface or near the surface layers.

| Chemical components to be studied |

starting from Ti |

| Concentration of the component to be studied, % mass |

0.01–100 |

| Range of the interatomic distances to be studied, nm |

0.15–0.8 (±1 %) |

| Error of the coordination number determination, % |

±10 |

| Error of the Debye factor determination, % |

± 40 |

Institute of Catalysis - a manager of the unique EXAFS spectroscopy station in Russia – specializes in the study of highly dispersed objects – catalysts, nano-materials. The procedures of sample preparation are developed for surveying the reaction-active compounds and catalysts under the inert conditions. The sample study is possible at the temperature from 77 to 900 K under the preset atmosphere conditions.

Instrument facilities

The station is mounted at the VEPP-3 storage ring located at the Institute of Nuclear Physics of the Siberian Branch of the Russian Academy of Sciences with an electron energy of 2 GeV. The following techniques have been realized: “on transmission”, X-ray fluorescence, total reflection, total photocurrent, X-ray stimulated optical luminescence.

Samples requirements

Sample – solid or liquid – in a quantity of 20 mg with respect to the chemical component to be studied. The solid samples – in the form of powder particle size not more than 0.1 mm. Regarding all the samples the preliminary consultation is necessary. In case of the sample study in inert conditions the ampoules are presented or the consultation about their preparation is provided.

Leading scientists and their research interests

Prof. D.I. Kochubey and Dr. V.V. Kriventsov. Study of the ultra-dispersed metals, cluster, oxide and sulfide materials.

Prof. D.I. Kochubey is the author of monographs “EXAFS spectroscopy” (1988) and “EXAFS catalyst spectroscopy” (1992), in Russia.